1 中南林业科技大学机电工程学院,湖南 长沙 410018

2 中南大学机电工程学院,湖南 长沙 410083

3 中南大学高性能复杂制造国家重点实验室,湖南 长沙 410083

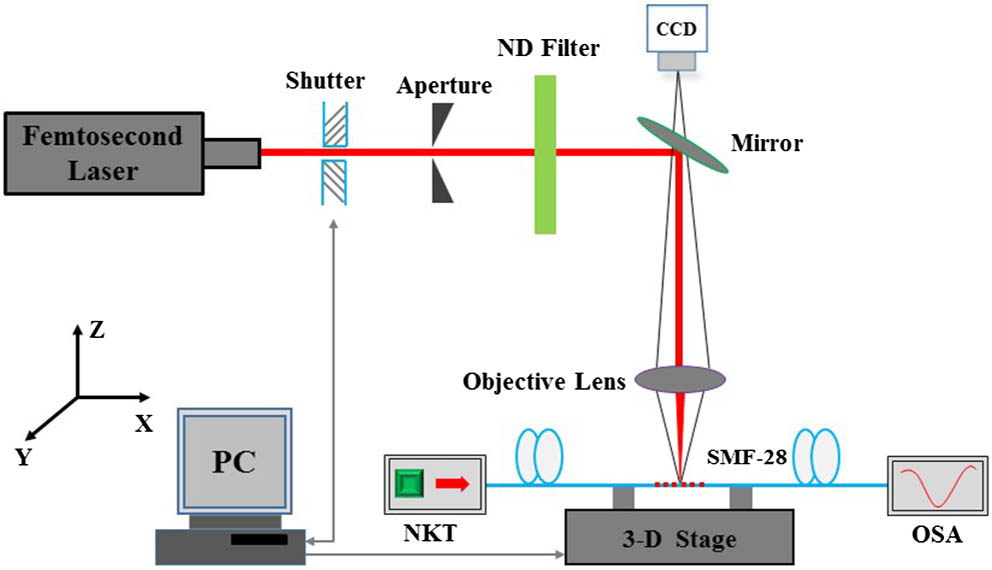

利用飞秒激光相位掩模加工方法制造光纤布拉格光栅(FBG),并研究了激光能量和曝光时间对FBG波长、反射率和带宽的影响规律。研究发现,随着曝光时间的增加,光纤的折射率调制量逐渐变大,耦合效率增大,反射率逐渐变大。当光纤耦合效率达到饱和时,反射率保持不变;当过曝光时,反射率轻微减小,光纤的平均有效折射率和折射率调制深度均变大,带宽增大。随着激光能量的增大,达到最大反射率所需要的曝光时间缩短,且FBG波长的红移量越多,带宽就越大。过大的激光能量会使平均有效折射率和折射率调制深度变大,从而导致FBG主谐振峰两边的旁瓣增多,影响光谱质量。另外,短波方向旁瓣的振荡比较显著,而长波方向则比较平顺。因此,在实际加工中需要选择合适的激光曝光能量和曝光时间。实验获得的最大FBG反射强度达到15 dB,且其光谱变化和理论分析一致。该研究为高质量FBG的制造和光谱特性优化提供了实验依据。

光纤光学 光纤布拉格光栅 飞秒激光 相位掩模法 光谱特性 带宽 中国激光

2023, 50(19): 1906001

Author Affiliations

Abstract

State Key Laboratory of High Performance Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

A novel fiber inline Mach-Zehnder interferometer (MZI) is proposed for simultaneous measurement of curvature and temperature. The sensor composes of single mode-multimode-dispersion compensation-multimode-single mode fiber (MMF-DCF-MMF) structure, using the direct fusion technology. The experimental results show curvature sensitivities of -12.82 nm/m-1 and -14.42 nm/m-1 in the range of 0 - 0.65 m-1 for two resonant dips, as well as temperature sensitivities of 57.6 pm/℃ and 74.3 pm/℃ within the range of 20 ℃ - 150 ℃. In addition, the sensor has unique advantages of easy fabrication, low cost, high fringe visibility of 24 dB, and high sensitivity, which shows a good application prospect in dual-parameters of sensing of curvature and temperature.

Mach-Zehnder interferometer curvature sensing temperature sensing simultaneous sensing Photonic Sensors

2020, 10(2): 171

Author Affiliations

Abstract

State Key Laboratory of High Performance Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

A high sensitive refractive index sensor based on the cladding etched photonic crystal fiber (PCF) Mach-Zehnder interferometer (MZI) is proposed, which is spliced a section of photonic crystal fiber between two single modes fibers (SMFs).The interference fringe of the MZI shifts with the variation of the ambient refractive index (RI). It is found that the RI sensitivity slightly decrease with an increase in the interference length. The sensitivities of MZI with 35mm PCF, 40mm PCF, and 45mm PCF are 106.19nm/RIU, 93.33nm/RIU, and 73.64nm/RIU, respectively, in the range of 1.333 to 1.381. After etched, the RI sensitivity of the MZI could be improved obviously. The RI sensitivities of the MZI with 35mm PCF are up to 211.53nm/RIU and 359.37nm/RIU when the cladding diameter decreases to 112μm and 91μm, respectively. Moreover, the sensor is insensitive to temperature, and the measured sensitivity is only 9.21pm/℃ with the range from 20℃ to 500℃. In addition, the sensor has advantage of simple fabrication, low cost, and high RI sensitivity.

Refractive index sensor Mach-Zehnder interferometer photonic crystal fiber hydrofluoric acid Photonic Sensors

2019, 9(2): 02126

Author Affiliations

Abstract

1 Hunan Key Laboratory of Super Microstructure and Ultrafast Process, School of Physics and Electronics, Central South University, Changsha 410083, China

2 The State Key Laboratory of High Performance Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

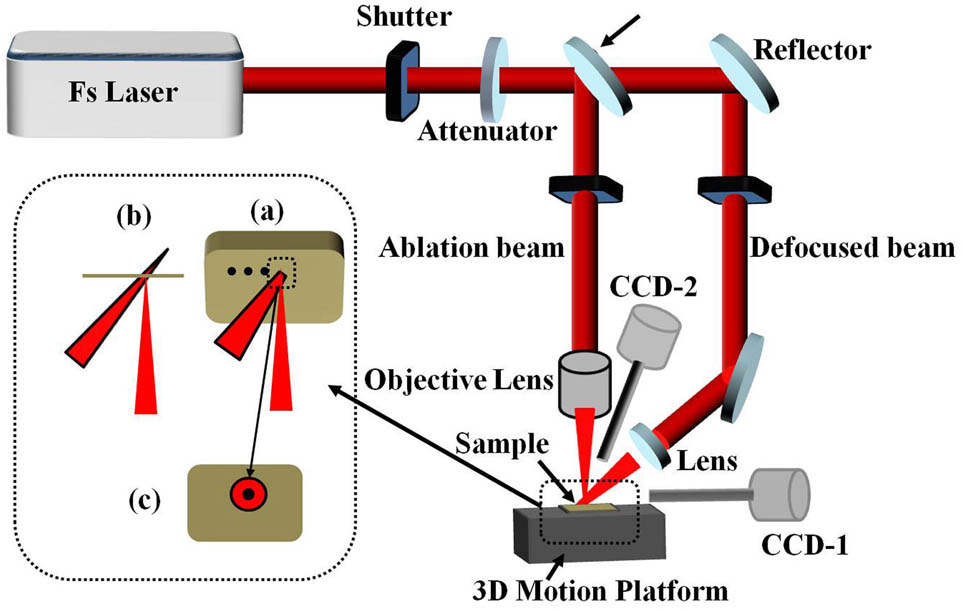

We evaluate the effects of the holes geometry drilled by a femtosecond laser on a stainless alloy with various defocused irradiation time, which ranges from 0 min to 1 h. The laser ablation efficiency is increased by a factor of 3 when the irradiation time is elevated from 0 to 30 min. Also, the morphology of the hole is observed by a scanning electron microscope, where the result indicates that the defocused irradiation time has a significant influence on the morphology changes. The reason for such changes is discussed based on the pretreatment effect and the confined plasma plume. As an application example, the microchannel is fabricated by a femtosecond laser combined with the defocused irradiation to demonstrate the advantage of the proposed method in fabricating functional structures.

140.0140 Lasers and laser optics Chinese Optics Letters

2018, 16(1): 011401

Author Affiliations

Abstract

State Key Laboratory of High Performance and Complex Manufacturing, Central South University, Changsha 410083, China

A simple technique is proposed for highly-efficient plane processing fully based on femtosecond laser beam shaping. The laser intensity distribution is transformed from a Gaussian to a donut shape. As the donut-shaped focus seems like a flat top from the side view, a plane with a high level of flatness is obtained directly by scanning once. By applying it to polishing experiments, the surface roughness can be improved significantly. The influence of scanning speed, laser pulse energy, and scanning times on the roughness is also discussed. Moreover, the scanning width can be flexibly controlled in a wide range.

140.7090 Ultrafast lasers 140.3300 Laser beam shaping Chinese Optics Letters

2018, 16(3): 031401

Author Affiliations

Abstract

State Key Laboratory of High Performance and Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

A constant elastic alloy is a widely used material with a high elastic modulus and an excellent wave velocity consistency. Different morphologies on the constant elastic alloy surface are observed through femtosecond laser irradiation. When the laser average fluence is set to 0.58 J/cm2 and 200 laser pulses, with the increasing depth of distilled water, the period of the laser-induced periodic surface structures (LIPSS) becomes shorter accordingly. The higher the ethanol concentration is, the more spot-shaped structures will be formed among the surface structures when the depth of the coverage of ethanol is 2 mm. The period of the LIPSS reaches its maximum when the concentration of ethanol is 80%.

320.2250 Femtosecond phenomena 220.4241 Nanostructure fabrication 100.0118 Imaging ultrafast phenomena Chinese Optics Letters

2017, 15(2): 021404

Author Affiliations

Abstract

The State Key Laboratory of High Performance Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

A fused silica glass micro-channel can be formed by chemical etching after femtosecond laser irradiation, and the successful etching probability is only 48%. In order to improve the micro-channel fabrication success probability, the method of processing a high-temperature lattice by a femtosecond laser pulse train is provided. With the same pulse energy and scanning speed, the success probability can be increased to 98% by optimizing pulse delay. The enhancement is mainly caused by the nanostructure, which changes from a periodic slabs structure to some intensive and loose pore structures. In this Letter, the optimum pulse energy distribution ratio to the etching is also investigated.

140.0140 Lasers and laser optics 230.7380 Waveguides, channeled Chinese Optics Letters

2017, 15(7): 071403

Author Affiliations

Abstract

State Key Laboratory of High Performance Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

We propose a high temperature-sensitive long period fiber grating (LPFG) sensor fabricated by using the femtosecond laser transversal-scanning method. The femtosecond pulses scan over the whole fiber core and some part of the cladding region; the modified regions are more extended. It is found that the LPFG-I fabricated by the transversal-scanning method shows higher temperature sensitivity and better temperature uniformity than that of LPFG-II written by the femtosecond laser point-by-point method. The LPFG-I with a temperature sensitivity of 75.96 pm/°C in the range of 25°C–400°C is measured. Moreover, in the range from 400°C to 800°C, a higher temperature sensitivity of 148.64 pm/°C and good linearity of 0.99 are achieved, while the temperature sensitivity of LPFG-II is only 95.55 pm/°C. LPFG-I exhibits better temperature characteristics, which, to the best of our knowledge, has the highest sensitivity in silica fiber temperature sensors.

060.0060 Fiber optics and optical communications 060.2370 Fiber optics sensors 140.7090 Ultrafast lasers Chinese Optics Letters

2017, 15(9): 090602

Author Affiliations

Abstract

State Key Laboratory of High Performance and Complex Manufacturing, College of Mechanical and Electrical Engineering, Central South University, Changsha 410083, China

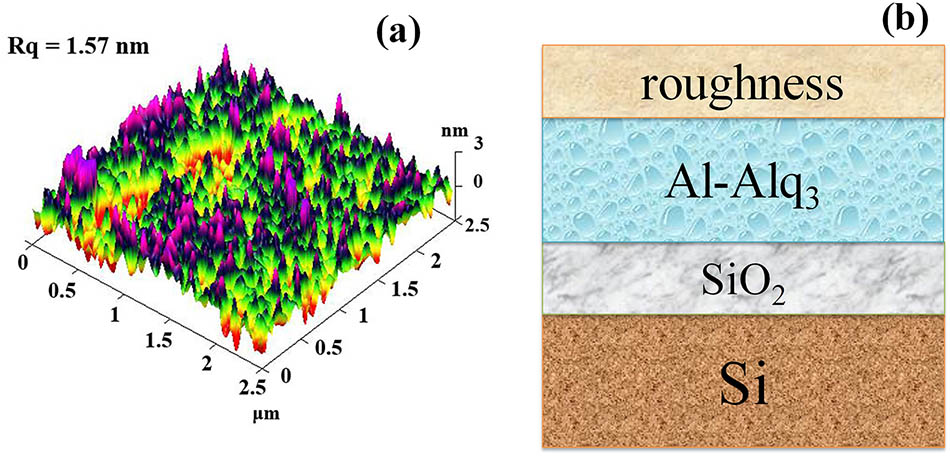

The optical constants, photoluminescence properties, and resistivity of Al-Alq3 thin films prepared by the thermal co-evaporation method on a silicon substrate are studied with various Al fractions. A variable angle spectroscopic ellipsometry is employed to determine the optical constants in the wavelength from 300 to 1200 nm at incidence angles of 65°, 70°, and 75°, respectively. Both the refractive indices and extinction coefficient apparently increase with increasing Al fractions. The intensity of photoluminescence spectra gradually increases with decreasing Al fractions due to intrinsic energy level transition of Alq3 organic semiconductor in the ultraviolet wave band. The resistivity decreases from 42.1 to 3.36 Ω·cm with increasing Al fraction from 40% to 70%, resulting in a larger emission intensity in photoluminescence spectra for the 40% Al fraction sample.

160.4890 Organic materials 120.2130 Ellipsometry and polarimetry Chinese Optics Letters

2017, 15(11): 111602

中南大学机电工程学院 高性能复杂制造国家重点实验室, 湖南 长沙 410083

传统的半导体工艺制作微流体系统中微通道, 只能对材料进行表面加工。飞秒激光具有极高的峰值功率和超短的脉冲持续时间, 能够对材料直接进行三维加工, 为高效率、高质量的微通道加工提供了可能。通过研究飞秒激光加工参数, 包括激光脉冲能量、扫描速度和偏振态对玻璃微通道的选择性腐蚀比影响规律, 发现当激光脉冲能量在2~10 μJ变化时, 微通道宽度变大, 2 μJ时微通道长宽选择性腐蚀比L/D高于其它脉冲能量参数, 但随着腐蚀时间的延长, 宽度变化越来越小, 最后趋于稳定; 当激光扫描速度在0.20~0.45 mm/s之间变化时, 随着腐蚀时间的延长微通道长宽选择性腐蚀比L/D逐渐增大, 但当速度增加到0.35 mm/s左右时选择性腐蚀比L/D增到最大, 此后呈现下降趋势, 同样随着腐蚀时间的延长, 腐蚀通道的宽度变化越来越小, 逐渐趋于平稳; 当偏振态从线偏振到圆偏振变化时, 线偏振时的微通道长宽选择性腐蚀比L/D更大。实验结果表明: 获得较大微通道长宽选择性腐蚀比L/D的最优加工参数为激光脉冲能量2 μJ, 激光扫描速度0.35 mm/s, 线偏振。

微流体系统 飞秒激光 微通道 选择性腐蚀比 microfluidic system femtosecond laser microchannel selective etching ratio